Laminated wood beams, created through layering thin sheets of wood, offer enhanced strength and sustainability in construction. They provide a superior strength-to-weight ratio, flexibility in design, and environmental responsibility. The global market for these beams is growing, driven by the demand for lightweight structural materials. Pricing varies worldwide due to labor rates, raw material availability, and local regulations, making thorough cost analysis crucial for international projects. Strategic sourcing from reputable suppliers can lead to cost savings without compromising quality.

“Laminated wood beams, a revolutionary component in construction, are gaining global popularity. This article delves into the international pricing dynamics of these innovative products, offering a comprehensive guide for builders and engineers worldwide. We explore the essential components and their impact on the market, analyze regional pricing variations, present real-world case studies, and provide strategies for cost-effective cross-border sourcing. Additionally, we discuss regulatory considerations to ensure quality in global trade, making this a one-stop resource for understanding laminated wood beams’ role and value in construction.”

- Understanding Laminated Wood Beams: Essential Components

- Global Market Overview for Laminated Wood Beams

- Pricing Factors: Regional Variations Explored

- Case Studies: International Construction Projects

- Cost-Effective Strategies for Cross-Border Sourcing

- Regulatory and Quality Considerations in Global Trade

Understanding Laminated Wood Beams: Essential Components

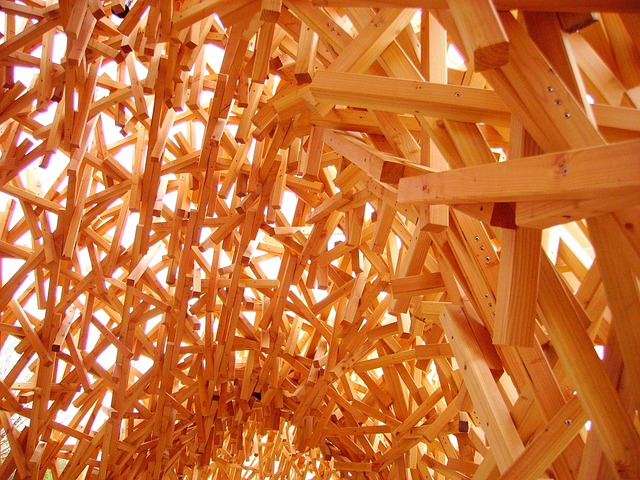

Laminated Wood Beams for Construction have emerged as a revolutionary solution in the building industry, offering both strength and sustainability. These beams are engineered by layering multiple thin sheets of wood with glue, creating a composite material that enhances structural integrity while minimizing weight. This innovative process not only makes them ideal for modern construction projects but also provides an eco-friendly alternative to traditional steel or concrete supports.

Understanding the essential components of Laminated Wood Beams is crucial for ensuring their longevity and effectiveness. The core strength lies in the lamination technique, which improves the strength-to-weight ratio compared to old wooden beams. This feature makes them easier to handle and install, reducing labor costs and project timelines. Moreover, these beams’ structural stability and durability make them suitable for various applications, from residential buildings to commercial structures, ensuring a sturdy foundation for any construction project. For those looking to invest in sustainable building materials, laminated wood beams offer both quality and environmental responsibility, making them an excellent choice for modern architecture and eco-conscious developers. Feel free to visit us at 18 Clifton St, Unadilla, NY 13849 anytime to explore more about these remarkable components.

Global Market Overview for Laminated Wood Beams

The global market for laminated wood beams is a dynamic and expanding sector, driven by increasing demand from the construction industry worldwide. This innovative material has revolutionized building practices, offering lightweight yet incredibly strong alternatives to traditional steel or concrete structural elements. Laminated wood beams, known for their superior strength-to-weight ratio, play a crucial role in modern architectural designs, enabling more open floor plans and creative building solutions.

With an eye on sustainability, many builders and architects are opting for laminated wood exterior applications due to its eco-friendly nature. These tailor-made laminated wood beams can be customized to fit various project requirements, ensuring efficient construction processes. When choosing the right laminated wood beams for your project, durability is a primary concern. By considering factors such as glue quality, laminating techniques, and material source, you can ensure the longevity of these structural components. For more insights, explore the comprehensive range available at unalam.com.

Pricing Factors: Regional Variations Explored

When comparing international pricing on laminated wood components, particularly laminated wood beams for construction, it’s crucial to understand that regional variations play a significant role in determining costs. These variations are influenced by several factors, including local labor rates, availability of raw materials, transportation and logistics infrastructure, and demand for specific products. For instance, countries with higher labor costs might price laminated wood beams more aggressively to remain competitive, while regions abundant in forest resources may offer lower prices due to easier access to raw materials.

Moreover, exploring wood beam alternatives for construction globally can reveal innovative solutions that balance strength and lightweight properties at different cost points. While laminated wood exterior applications are gaining popularity for their aesthetic appeal and environmental benefits, price comparisons must consider not only production methods but also the longevity and performance of these alternative materials. For those seeking a compare laminated wood beams pricing analysis, platforms like unalam.com offer valuable insights, allowing users to navigate the global landscape and find the best value for lightweight yet strong laminated wood components tailored to their construction needs.

Case Studies: International Construction Projects

In international construction projects, the choice of materials can significantly impact project costs and outcomes. Case studies from around the globe highlight the diverse pricing landscapes for laminated wood components, particularly beams. For instance, a recent study compared the use of laminated wood beams for construction in both Europe and North America. The research found that while the raw material costs were comparable, labor expenses varied widely due to differing construction methodologies and regulations. This variability led to significant price differentials for similar laminated wood beam products.

These findings underscore the importance of careful material selection and cost analysis when embarking on international construction projects. For instance, a lightweight yet strong laminated wood beam might be ideal for high-rise buildings in urban areas where space is at a premium. Conversely, laminated wood beams offering superior structural integrity could be more suitable for rural or remote locations where traditional concrete or steel structures are less feasible. Visitors interested in exploring these options can visit us at 18 Clifton St, Unadilla, NY 13849 anytime to learn more about our range of laminated wood components, including their diverse applications from interior to exterior design projects.

Cost-Effective Strategies for Cross-Border Sourcing

When considering cost-effective strategies for cross-border sourcing of laminated wood components, especially for construction purposes like those involving laminated wood beams, one must explore international markets strategically. The global supply chain offers a wealth of opportunities to source affordable laminated wood construction materials without compromising on quality. This approach can significantly reduce costs, especially for projects requiring substantial amounts of wood beams.

One effective tactic is to research and partner with reputable suppliers who specialize in wood products from various countries. These suppliers often have established networks and expertise in navigating international trade, ensuring you access the best deals on wood beam alternatives for construction. Additionally, they can provide guidance on custom solutions and innovative ways to replace old beams with laminated wood aesthetically pleasing while maintaining structural integrity. For personalized advice and a tailored approach, give us a call at (607) 369-9341.

Regulatory and Quality Considerations in Global Trade

When comparing international pricing on laminated wood components, especially for construction purposes like Laminated Wood Beams, it’s crucial to consider regulatory and quality aspects that vary across global markets. Each country has its own set of building codes, safety standards, and environmental regulations that impact material imports. For instance, some regions might have stricter requirements for chemical treatments or specific certification standards for structural integrity, influencing both the cost and availability of Laminated Wood Beams for Construction.

These variations can pose challenges for manufacturers and builders aiming to source budget-friendly alternatives while maintaining quality. However, this also opens up unique design possibilities, as different regulations encourage innovation in material usage and construction methods. For example, designers are exploring creative ways to incorporate laminated wood into architectural projects due to its strength, versatility, and environmental friendliness. To stay updated on the latest trends and ensure compliance with global standards, visit us at 18 Clifton St, Unadilla, NY 13849 anytime. This approach allows for informed decision-making in navigating the global market for laminated wood components while considering both cost-effectiveness and design potential.

When sourcing laminated wood components globally, understanding the international pricing landscape is key. By exploring regional variations, considering cost-effective strategies, and navigating regulatory aspects, construction projects can benefit from the advantages of cross-border sourcing. The case studies presented highlight successful international collaborations, emphasizing the potential for saving costs without compromising quality when utilizing laminated wood beams for construction in diverse markets worldwide.